Our ongoing investment strategy

At Acorn Web we truly feel that to support our business and our loyal customers it is vital to stay abreast of technological advances and invest in new equipment at the right time.

In recent years there have been many pressures caused by the covid19 pandemic, global conflicts and industrial strike action. The economic consequences have included supply shortages, rising material costs, rising labour costs and energy hikes. Such pressures could have been very damaging to Acorn had we not stuck to our strategy of increased specialisation and had we not decided upon several positive investment actions.

Our customers tell us that they value print, but that it must remain competitive against the many other communication channels on offer to them. To see how we’ve managed to maintain our high performance and preserve best value whilst cutting time, material and energy from the process please click on each asset below: -

ePS Technique

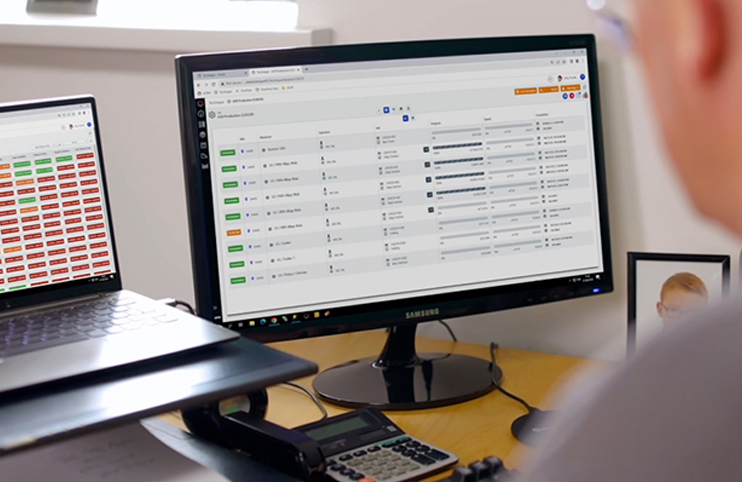

In 2013 and with sales turnover of just £16 million Acorn needed to replace its aging MIS system and it needed a software partner that shared its vision for operational excellence.

Pre-press plate stream & automatic plate bender

Our Pre-Press department was revamped in 2019 and this was part of a large investment spend that captured the latest pre-press technology, a new web offset press and additional warehousing.

Lithoman Web 32pp

Installed in 2019 this press was the focal point of a £6 million investment. It was bought to respond to the changing dynamic in the marketplace, where lower more frequent magazine and catalogue runs with multiple versions were now prevalent.

Rotoman Web 16pp

This press runs fast at 60,000 impression per hour and it is particularly strong at producing A5 which is an important format offering for many of our publishing and retails customers.

KBA sheetfed B1 UV

Our sheetfed press runs magazine, brochure and catalogue covers day and night! This current asset was one of the first investments the M.B.O team made back in 2014, and it was also an investment that delivered several strong benefits for customers.

Muller Bravo & Prima Plus

The company’s capabilities were improved in late 2022 and early 2023, with the introduction of two high speed saddle stitchers, bringing the total number of machines to four.

Civiemme Cobot Bundle Stacker

Say hello to Jonny 5!

Follow us on social media